We detect and document thermal anomalies in electrical equipment.

Infrared surveys are cost effective.

This is a non-destructive technology which causes no disruption of service…no shut down is required!

If you are a facility manager, maintenance manager, building owner…responsible for safety, production and repair at your facility, you cannot afford to be without a regular infrared (IR) thermographic survey of your electrical switchgear, distribution system and mechanical equipment.

The National Fire Protection Association (NFPA) 70B §11.17.5 suggests that every commercial and industrial building in the United States should have an IR survey at least once a year.

Increasingly, insurance companies are requiring IR surveys of electrical and mechanical systems for their insured. Some companies may even offer discounts if you do.

Avoid costly downtime, lost production, unnecessary repairs, and dangerous catastrophic failures. Take advantage of Electrical Infrared Thermographic Surveys to increase uptime, productivity and profitability.

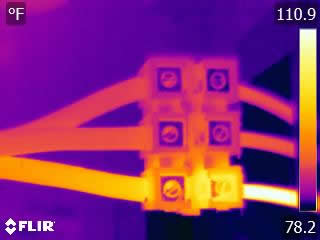

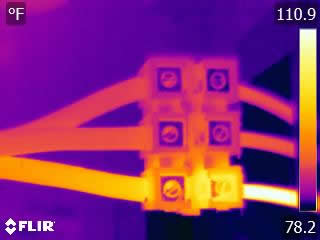

By far, the most popular and widely used application of infrared thermography is electrical switchgear testing. No other commercial application has achieved the level of interest than that of electrical infrared thermography. Daily, the electrical switchgear in thousands of buildings are checked by our thermographers all over the country. Electrical Infrared is now an integral part of any facility manager's preventative/predictive maintenance (P/PM) program.

Why Use Our Service?

- Reduce Downtime

- Increase Equipment Life

- Lower Risks

- Comply with Electric Codes

- Lower Repair Costs

- Increase profits

- Save on Insurance

- Prevent Catastrophic Failures

- Save Lives!

Back to Services

Back to Services

Roofing

Infrared testing is used to detect water damage and active leaks beneath the roof surface, allowing the opportunity to repair the leak before it can spread further.

Thanks to our partnership with United Infrared, we can also offer aerial thermography more affordably than ever before. This is great for those hard-to-reach roofs.

Building Diagnostics

Infrared testing is used to detect heating and cooling loss or moisture problems due to insulation deficiencies or construction issues. This can lead to huge energy savings in your facility.

Electrical

Annual infrared surveys of your electrical equipment can save lives, production costs and downtime. Switchgear testing is the most popular application of infrared testing technology because it's non-disruptive (no shut down required), non-destructive and it works.

Mechanical

Motors can be monitored to allow downtime to be scheduled, allowing a plant to be pro-active instead of reacting to problems after they happen.

Bearings on drive shafts and conveyor systems can give good indicators of impending failure, allowing for replacement on your schedule instead of shutting down operations during peak production periods.

Blockwall/CMU

Destructive CMU blockwall testing can only show a very small sample size and X-ray is a very expensive technology. Infrared provides a much more thorough and affordable option to provide quality control to new CMU construction.